Biodiesel blending: a guide to the process and technologies

As the world shifts towards more sustainable forms of energy, biodiesel has emerged as a promising alternative to traditional petroleum-based fuels. Biodiesel blending, the process of combining biodiesel with petroleum diesel to create a fuel that is more environmentally friendly and cost-effective, is becoming increasingly popular.

In this technical article, we will delve into the intricacies of biodiesel blending and provide a comprehensive guide to the process and technologies involved. We will also highlight the expertise and experience of ISOIL, a leading company in the field of biodiesel fuel measurement systems:

- What is biodiesel blending

- The process of blending biodiesel in the oil and gas industry explained in 4 steps

- Key benefits of biodiesel blending

- Blending biodiesel with traditional diesel to create a renewable fuel source

- The process of blending biodiesel in the oil and gas industry

- ISOIL Vega 3 multi counter flow computer for biodiesel blending

What is biodiesel blending?

Biodiesel blending is the process of mixing pure biodiesel (B100) with conventional petroleum diesel to create a final blend that offers enhanced sustainability, improved lubricity, and reduced greenhouse gas emissions. The blend percentage determines the fuel’s characteristics, performance, and regulatory compliance.

Common biodiesel blend types (B2, B5, B10, B100)

|

Blend Type |

Description |

Typical Use Cases |

|

B2 |

2% biodiesel, 98% petroleum diesel |

Helps meet minimum renewable fuel requirements; improves lubricity |

|

B5 |

5% biodiesel |

Widely accepted by OEMs; standard in many regions |

|

B10 |

10% biodiesel |

Enhanced carbon reduction; may require cold-flow considerations |

|

B20 |

20% biodiesel |

Popular in commercial fleets; balanced performance and sustainability |

|

B100 |

100% biodiesel |

Used in specific applications; requires dedicated infrastructure |

These blends vary by region depending on fuel standards, emission reduction targets, cold-weather performance, and industry requirements.

The process of blending biodiesel in the oil and gas industry explained in 4 steps

While blend ratios depend on regulations and customer requirements, biodiesel blending must always guarantee accuracy, homogeneity, and regulatory compliance. In the oil & gas industry, blending typically happens in refineries, pipeline terminals, loading racks, and storage facilities.

Below is a clear, step-by-step outline of the process:

STEP 1 — Mixing & homogenization

Depending on the method:

- In-line blending: turbulent flow ensures consistent mixing.This is the method used in Isoil Impianti solutions.

- Splash or in-truck blending: agitation during transport completes mixing.

- In-tank blending: recirculation pumps or mechanical mixing ensure homogeneity.

STEP 2— Selection of blending method

Common architectures include:

- Sequential blending

- Ratio blending

- Side-stream blending

- Differential blending

(ISOIL VEGA 3 supports all of these configurations.)

STEP 3 — Flow measurement & dosing

- Precision flow meters monitor each component.

- The control system calculates the exact quantity of biodiesel needed to reach the target blend ratio.

- Biodiesel is introduced into the petroleum diesel stream (in-line), into a tank, or via sequential dosing.

STEP 4 — Verification, loading & documentation

- Final blend density checks confirm the correct biodiesel percentage (by others)

- The blended fuel is transferred to tank trucks or storage tanks.

- The system logs all blending parameters for regulatory compliance.

ISOIL solutions enable real-time control, enhanced traceability, and advanced automation at each stage.

Key benefits of biodiesel blending

- Environmental performance: reduced CO₂ emissions; lower particulate matter, hydrocarbons, and carbon monoxide; supports corporate sustainability and renewable fuel mandates.

- Improved fuel properties: increased lubricity that helps extend engine life; cleaner and more efficient combustion compared to traditional diesel.

- Operational efficiency: faster loading times through in-line blending; fewer storage tanks required; enhanced process control that minimizes variability and errors.

- Cost savings: reduced need for premixed fuel infrastructure; lower operational and logistics costs; ability to optimize blend ratios based on market prices and seasonal conditions.

Need support for integrating biodiesel blending into your operations?

ISOIL provides advanced measurement and control systems for accurate, reliable, and compliant biodiesel blending. Our experts can help you design the most efficient solution for your refinery, terminal, or loading facility.

Contact us for more information about our biodiesel blending technologies and measurement solutions.

Contact us

Blending biodiesel with traditional diesel to create a renewable fuel source

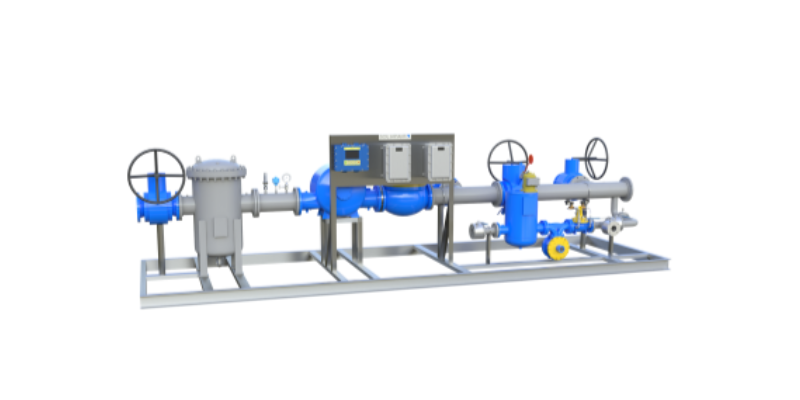

Blending biodiesel with traditional diesel to create a renewable fuel source not only reduces the carbon footprint of transportation but also promotes the use of renewable resources, making it a more sustainable fuel option. ISOIL, a leading provider of fuel measurement systems, is capable of supplying biodiesel blending solutions that are integrated into the tank truck loading process. This in-line blending system offers several advantages,

including:

- savings in terms of cost and production time scales;

- blend flexibility;

- quality of the blended product.

By blending biodiesel and traditional diesel during loading, ISOIL solution eliminates the need for an extra blending step, thus reducing production time and costs. The flexibility of the blend ratio allows for customization according to specific requirements, while ensuring

the quality of the end blend.

Do you need more info about the biodiesel blending process and how to integrate it in your operations?

Contact us

The process of blending biodiesel in the oil and gas industry

The biodiesel blending process in the oil and gas industry typically involves combining petroleum diesel with biodiesel at a specific ratio. This ratio can vary depending on the desired properties of the end product (such as cold-flow performance, lubricity, and emissions profile) and local regulations or fuel standards.

In practice, blending biodiesel with petroleum diesel is commonly carried out at refineries or loading terminals, where operators can control quality and ensure consistency across batches. Depending on the infrastructure and logistics, blending may be performed inline during fuel transfer or using batch-blending methods, with final checks to confirm the blend meets required specifications before distribution.

Learn more about all the fuel blending types, benefits and equipment

The process requires careful monitoring and control of the blending process to ensure the quality and consistency of the final blend. The use of specific equipment and technology, such as ISOIL biodiesel blending solutions, can help to streamline the process, improve accuracy and precision, and reduce operational costs. According to the customer’s needs, the system can be designed to be installed on the transfer line to the tank or directly at the loading point.

ISOIL Vega 3 multi counter flow computer for biodiesel blending

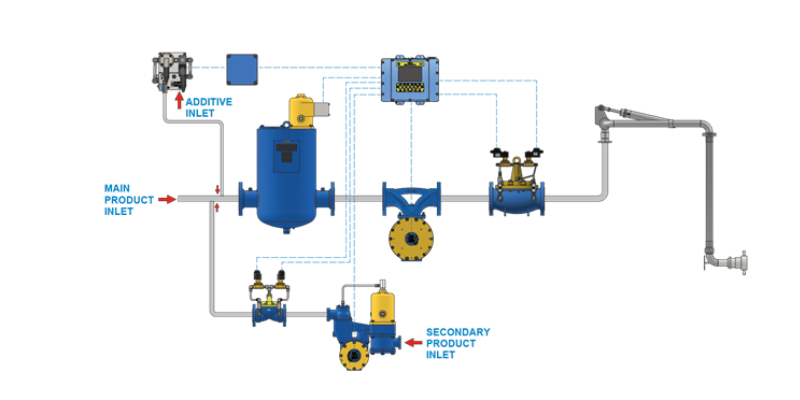

The heart of any biodiesel blending process is the control system, which must be capable of managing various blending architectures to suit the specific application needs and regulatory framework.

In this context, ISOIL VEGA 3 electronic counter, a state-of-the-art solution, offers advanced functionalities and high levels of accuracy and reliability. The VEGA 3 system supports various blending architectures, including:

- sequential blending;

- ratio blending;

- side stream blending;

- differential blending.

Each of them has unique benefits and challenges. Sequential blending involves blending two or more components in a specific order to achieve a desired final blend, while ratio blending involves blending two or more components in a fixed ratio to achieve a consistent blend,

measuring the two components separately. On the other hand, side stream blending achieves the same result by measuring the secondary product (biodiesel) and the blended product.

The VEGA 3 electronic counter offers flexible and precise control over each of these blending architectures, allowing for accurate and reliable blending operations in compliance with applicable regulations. Whether for small-scale blending operations or large-scale industrial applications, ISOIL VEGA 3 is a versatile solution for biodiesel blending.

For information about our solutions in biodiesel blending measurement, contact us!

Contact us

Contact us for more information about our services and products

Form sent successfully

Error