Pulse Emitters

Pulse emitters allow transforming energy into an electrical signal readable by counters and other digital devices.

Specifically, the pulse emitter EM6422 converts the rotary motion of a PD meter into electrical signal, enabling the interface with ISOIL electronic counters (VEGA T, VEGA 3) or third party devices.

When it is supplied installed on a new ISOIL meter, the EM6422/A emitter, thanks to its innovative design, also acts as seal of the meter shaft, ensuring magnetic coupling and making the meter virtually leakproof. In its EM6422/B version, it can be retrofitted on meters supplied in the past, thereby assuring compatibility with previous supplies.

Isoil has also developed adapting flanges for fitting the EM6422 emitter on several third party meter models.

- EM345 to be fitted inside the Veeder Root mechanical counter. Intrinsically safe construction, single channel, suitable for remote signal transmission.

- EMT2-2 to be fitted inside the Veeder Root mechanical counter. Explosion-proof execution with amplified pulse output, with double quadrature pulse train.

EM6422 pulse emitter operation

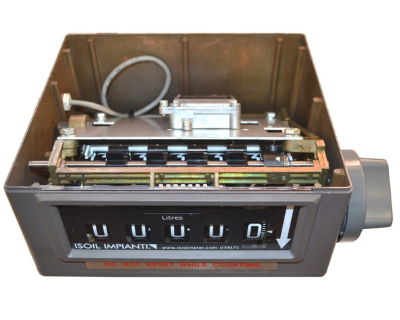

EM6422 pulse emitter consists of an aluminum casing split into two compartments divided by an aluminum wall.

How it works:

- In one of the two compartments, a small shaft installed on a roller bearing is connected on one end to the output shaft of the PD meter and on the other end to a magnet.

- Inside the adjacent compartment, another magnet detects the rotation of the shaft and causes an electronic circuit to generate electric pulses. Therefore there is no need for dynamic seals that can cause leaks due to wear over time.

- The housing is closed by a cover with O-ring and has a threaded female inlet for cable entrance by conduit or by cable gland.

- The electric wiring is made through a removable and easily accessible terminal block.

Versions of EM6422 pulse emitter

There are two different versions of the EM6422 pulse emitter manufactured by ISOIL: pulses transmitted and can bus transmitted.

Pulses transmission

In this first version, the shaft of the EM6422 is connected to the meter shaft. Each rotation of the rotor equals 64 or 256 pulses which are generated on two channels (A and B) with a phase shift of 90° electrical degrees. An electrical circuit monitors the coupling between the magnet and the sensor: any malfunctioning will result in a pulse transmission on a single channel only. The electronic counter receives a number of pulses proportional to the delivered volume enabling the user to check:

- The correct transmission and operation of the EM6422 by simply comparing the count of both channels;

- The flow direction by analyzing the pulse sequence.

CAN bus transmission

The encoder is provided with a microcontroller counting the pulses from a magnetic sensor (A, B and Index channels). The number of generated pulses (64 or 256 pulses per round) and the frequency are transmitted to the flow computer through a CAN bus connection by means of an ISOIL proprietary protocol. This protocol includes a key controller to avoid tampering with legally relevant data.

The integrity of the electronic circuit can be checked by monitoring the sequence of A, B, and index channels, and the coupling between the magnet and sensor. Any malfunction can be immediately detected by monitoring the status of the CAN bus protocols. Electronic counter VEGAII/VEGAT/VEGA3 linked with EM6422 CAN bus requires specific firmware.

Mounting of ISOIL pulse emitter

Pulse emitters can be fixed to all ISOIL PD meters with a mechanical counter or with a mechanical counter and ticket printer. The cable used to connect the EM T2-2 passes through a side hole in the cover while a polymeric cable gland guarantees the side-hole to be watertight. Upon request, an explosion-proof micro-switch can be installed in order to send an electric signal each time the mechanical counter is reset.

Contact us

Contact us for more informations about our services and products

Form sent successfully

Error