VEGA T2 for Aviation Refuelling Operations

Electronic Counters

The electronic counter plays a key role in both measuring and automation of loading procedures.

From a metrological point of view, in combination with the flow rate meter (PD, mass, turbine etc.) the electronic counter can provide, depending on the version, either on the user display or to remote devices through the communication ports:

- the measurement, in the desired unit of measure

- the temperature compensated volume (typically 15°C)

- the pressure compensated volume

- the flow rate

- the average flow rate

- the average loading temperature

- ticket printing

- etc.

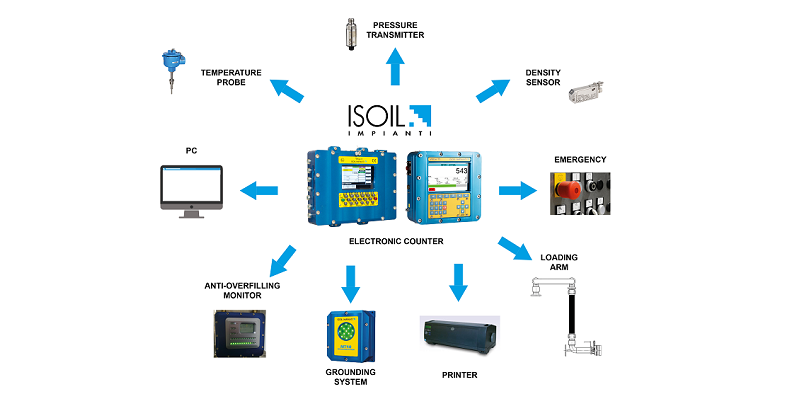

Automation

From the point of view of automation, on the plant side, the electronic counter acquires signals from various types of transducers (pressure, temperature, density), the status of a number of external devices (grounding, anti-overflow, position of the loading arm, emergency button, etc.) to verify that the safety and operational conditions of the transfer are met. On the basis of this check, it checks any root valves, the flow rate control valve, pump status, additive injection system, or any other devices to deliver the required amount of product according to the intended operational and safety procedures.

The electronic counter is the core of the measuring and automation system that manages the signals from the field. At the same time, it carries out two-way communication with the control room; it sends information on the loading status and receives indications from the Terminal Automation Software, under whose supervision and control it operates.

ISOIL offers three different models of electronic counters:

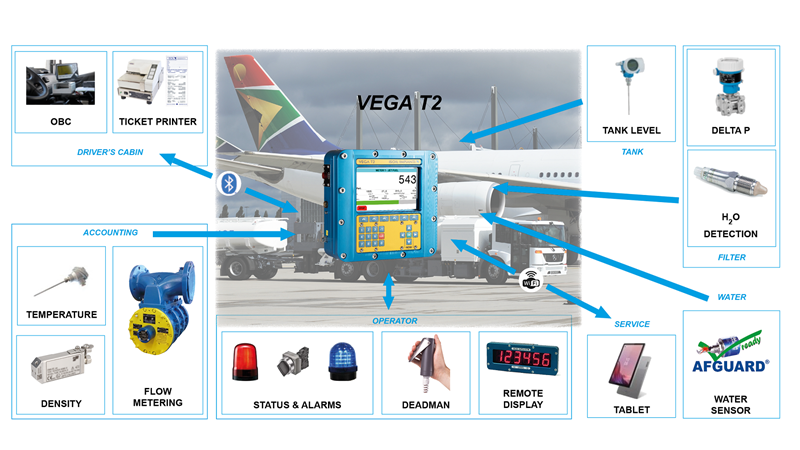

VEGA T2 is the ultimate solution in terms of electronic register & controller for the into plane refuelling / defueling applications, either on mobile vehicles or on refuelling modules, and for oil terminals as well.

Applications

AIRCRAFT REFUELLING OPERATIONS

- On board of a hydrant dispenser or refueller, VEGA T2 can manage up to 2 Meters, controlling both the Underwing and the Overwing refuelling Meters separately and at the same time as well.

- In terms of Automation, VEGA T2 can interface, monitor, and manage information from several sensors on the vehicle, such as the water contamination sensors, the differential pressure transmitter or switch, the water in sump sensor, level sensors, deadman etc.

- Thanks to its extended communication features (serial lines, Ethernet Port, Bluetooth compatible peripheral and Wi-Fi), VEGA T2 can make all the measure and automation information available to remote units such as on-board computer or external devices for data acquisition and transmission. At the same time VEGA T2 drives a ticket printer directly, with legally relevant functions.

OIL TERMINAL OPERATIONS

- For loading & unloading applications within the oil depots or for custody transfer lines, VEGA T2 can be matched with almost any type of flow meter and, by acquiring the information from optional temperature, pressure and density sensors it can provide a legally relevant measure of the quantity delivered.

- VEGA T2 can control the preset valve and monitor the signals coming from the devices around it, thus granting safety of all the operations.

- Thanks to its extended communication features (serial lines, Ethernet port, Bluetooth compatible peripheral and WiFi connection), VEGA T2 can communicate with the control room, share the delivery information and receive the instructions to operate from a SCADA or TAS.

VEGA T2 for Terminal Operations

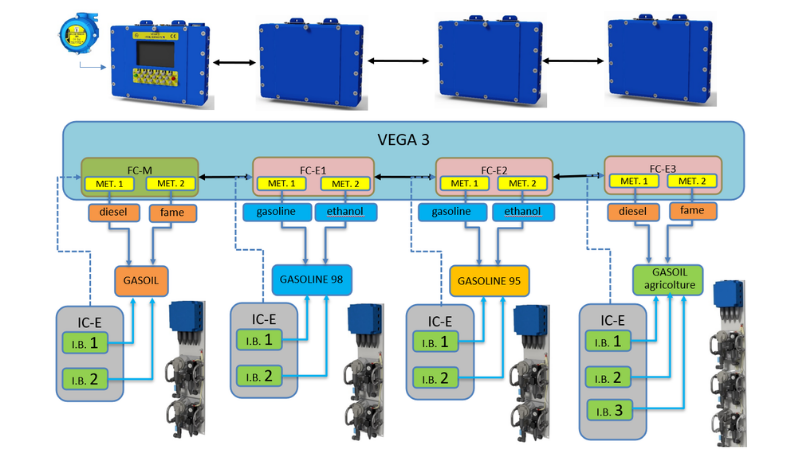

Vega 3 is a modular system capable of managing, in its most comprehensive execution, up to 6 loading arms / 12 counters, 48 additives and up to 16 different products.

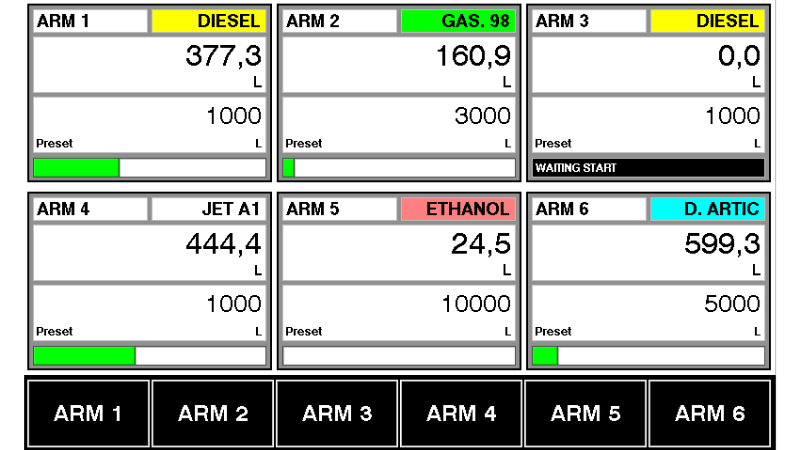

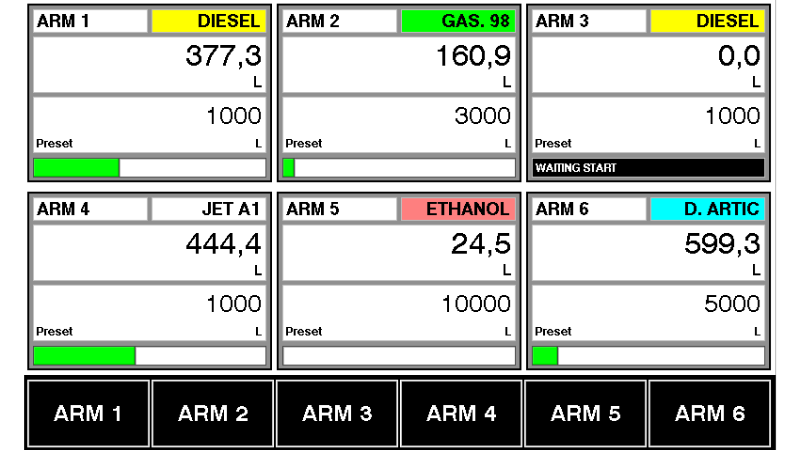

Examples of loading management screens with VEGA 3

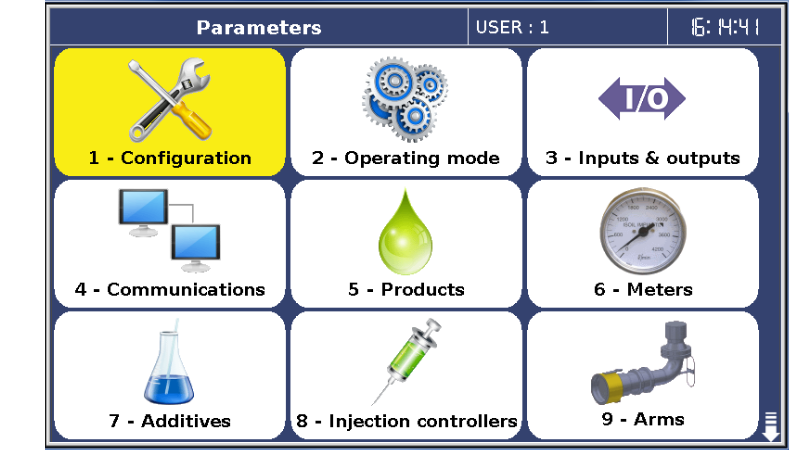

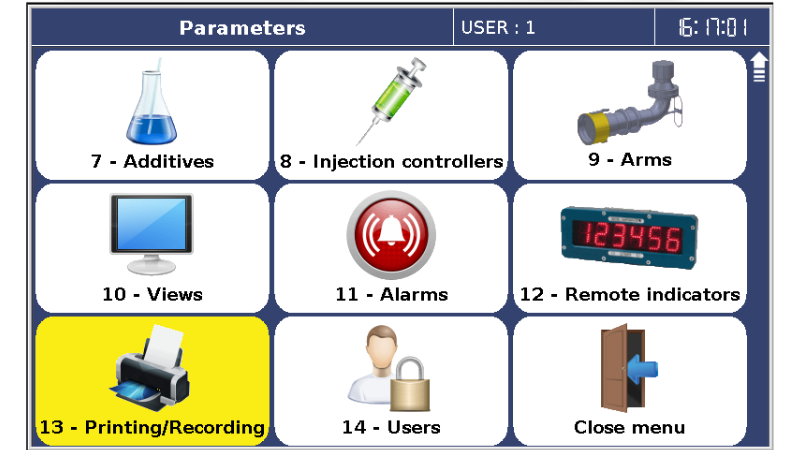

Examples of options and settings screens of VEGA 3

Examples of options and settings screens of VEGA 3

Examples of loading management screens with VEGA 3

Examples of loading management screens with VEGA 3

Examples - VEGA 3

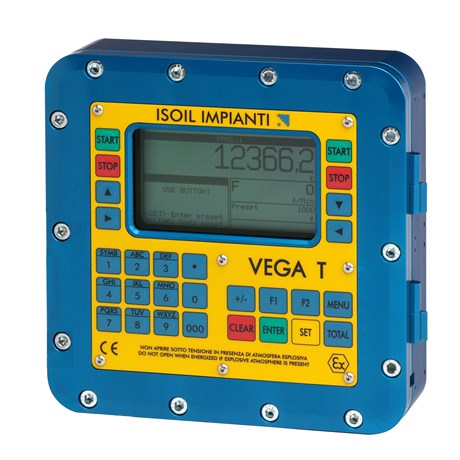

Available for fixed installation (deposits and transfer lines) and for movable mobile installations (on road tank trucks and aircraft refuellers), VEGA T is the optimal solution for all applications that have type 1 connection: 1 counter - head.

Functions

Compact-sized, it offers all the functions required by most applications of average complexity.

For two specific applications, VEGA T is available in the special DOUBLE COUNTER version:

- for aircraft refuellers, it manages two counters simultaneously, one for underwing refuelling and one for overwing refuelling

- for tank trucks with gravity unloading, it manages two meters at the same time, typically one for petrol and one for diesel fuel, to avoid product contamination

Contact us for more informations about our services and products

Form sent successfully

Error