Terminal automation system: what is and how it works

A Terminal Automation System\software (i.e. TAS) is essential for the oil and gas industries. It can automate different manual processes in an oil terminal, specifically around truck loading and unloading area, additive injection, blending and control of rail/pipeline/marine operations/tank transfers, providing tailored documentation and reporting. A good terminal automation system must be flexible and work with metering skid flow computer and, optionally, with weight scales and tank gauging systems.

On this page, we will focus on:

What is a TAS (Terminal Automation System\software)?

An automated terminal system allows remote control of loading/unloading points in oil terminals, monitoring and controlling the loading process of tank trucks to ensure reliable and safe operations. It can also provide reporting features (daily, weekly, monthly or yearly based) that allow a deeper control of the terminal activities, both in terms of operation and safety levels.

Do you need more info about our terminal automation systems?

Contact us

Key benefits of terminal automation systems

Process automation offers several benefits for oil metering installations.

Process optimization

The work of the entire staff is completely optimized. Thanks to the sophisticated computerized control systems it is possible to monitor the entire liquid measuring chain within the loading facilities.

Elimination of errors

Thanks to our systems, the possibility of accidental or even voluntary errors is nullified with regard to the preparation of administrative and fiscal documents both for loading and for travel for each load carried.

Full monitoring

Each truck can be constantly monitored during the entire loading process. The monitoring also includes automatic control and implementation of all safety procedures, before carrying out the subsequent stages of delivery.

Verification of distribution

Other features: no risk of overload and attempts at fraud, constant control of the product with respect to the types and quantities supplied, automatic preparation of the necessary transport documents, thus reducing the overall loading time for each vehicle.

TAS (Terminal Automation Systems) by ISOIL

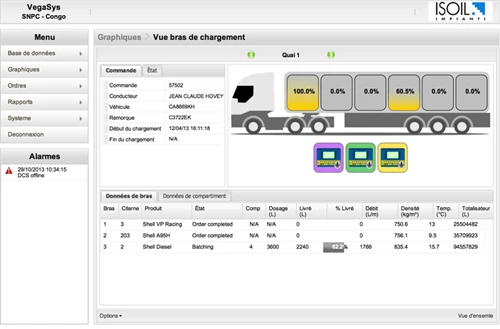

ISOIL provides complete solutions for the automation and remote control of loading and unloading operations in oil depots. The Terminal Automation System (TAS) supervises and manages the entire tank truck loading process, ensuring efficiency, reliability, and safety.

The system is highly flexible and configurable, allowing integration with different modules according to plant design or specific customer requirements. The ISOIL TAS is designed to operate seamlessly with ISOIL VEGA T2, VEGA 3 electronic counters, and related instrumentation.

Key system features include:

- Loading authorisation and safety interlocks

- Generation of bills of lading and delivery reports

- Driver PIN or card validation and order authorisation

- Preset quantity validation and dynamic display of instrument status

- Multi-compartment loading and reconciliation functions

- Additive verification and secure remote order entry

- Integration with third-party control interfaces

- Real-time monitoring of flow rate, temperature, density, and preset quantities

- Graphical overview of tank and vehicle status, including driver and load details

- Continuous event logging of instruments activities

- Full connectivity via the site’s local area network (LAN)

SBR Badge Reader for terminal automation

Automation of tank truck loading procedures includes user recognition as a safety and fraud prevention requirement. Among the numerous available methods with various degrees of security (from simple PIN to biometric devices), badge reading is a very widespread method. The SBR contactless badge reader for installation in classified areas reads the badge in radiofrequency and holds it inside the specific housing throughout the entire loading operation. Its removal entails the immediate interruption of procedures.

Designed as an important component of the terminal automation procedure, it can work directly combined with the electronic counter (VEGA T2 and VEGA 3) in MASTER mode or as a remote device in communication with the control room in SLAVE mode.

Terminal automation system architecture — how TAS and SBR Reader work together

Here is a typical scenario of how these two devices would work together:

- When a truck arrives at the terminal, the loading/unloading procedure must be authorized.

- Before the operator/truck driver can start the loading/unloading, the system needs to verify who is operating, for safety, security, fraud prevention, compliance reasons (especially in oil & gas / dangerous goods terminals). That is where the SBR badge reader comes in: the driver presents its badge to the reader, the reader validates the badge, and only if the badge is valid the procedure will continue.

- The badge reader is physically installed in the “classified area” (hazardous zone, e.g., Zone 1) so that the operator must pass the badge check right at the loading point. The reader sends the badge code (via serial communication) to the control system.

- The TAS software will integrate this badge‐authorization step as part of the “load authorization” process. So, for example: the TAS intercepts the badge reader event → verifies the badge is authorized for that loading point/truck/product → if yes, enables the pump/valve/instrumentation to proceed; if not, it blocks the operation.

- The badge reader also often drives external devices (e.g., barrier, traffic light at depot entrance \ exit) via the relay output: once the badge is validated, the relay can lift barrier or change light to green, instructing the driver to proceed.

- The TAS meanwhile logs the event: time, which badge, which truck/position, which product, what volume/mass is moved, etc. This links the operational, security, and measurement layers together (driver identity, product movement, instrumentation, documentation).

Do you need more info about our Terminal Automation Systems?

Contact us

Contact us for more information about our services and products

Form sent successfully

Error