Flow meter calibration: how it works and which tools to use

Many industries must meet certain standards in their fluid and gas measurement processes. A good flow meter must be calibrated correctly to ensure maximum accuracy.

A flow meter is an important device to measure the flow rate of fluids or gas in the Oil & Gas, petrochemical and manufacturing industries. Among these fields accuracy is of course an essential feature. Therefore, flow meter calibration is a milestone activity in reaching the highest standards.

Flow meter calibration is a process that compares the predefined scale or metering of a so-called flow meter to a standard scale of measurement and allows adjusting its performance to conform to this standard.

- Flow meter calibration: what is it?

- How to calibrate a flow meter

- A step-by-step guide to calibrate a PD meter with a Master Meter

- ISOIL test room

What is flow meter calibration?

Calibration is essential in a broad range of industries that require high-accuracy measurements with a negligible percentage of error. Some examples: tank trucks loading and unloading in oil terminals, pipeline transfer and aviation refueling operations. Therefore, all manufacturers are foreseeing a calibration step before each and every flow meter is delivered on site, by comparing and adjusting their metering to correspond with a preset standard, national or international. PD flow meter manufacturers can both adjust their equipment in-house after production or send it to an independent calibration laboratory.

In detail, the process of calibration requires the comparison of the measurement made by a flow meter in operation with that of a reference standard in the same conditions: flow meters are tested on a range of flow rates and they are then adjusted to the standard scale.

Periodic recalibration is indispensable to keep the device in optimal condition so that the error conforms to the range required by the standard.

How to calibrate a flow meter

Calibration can be performed by using:

- Proving tanks

- Master meter

They are both very precise and reliable measurement systems. Master meters are more flexible and can be easily transported near the flow meter to be calibrated: they are therefore recommended in situations where rapidity is essential.

A step by step guide to calibrate a flow meter with a Master Meter

To ensure precise PD meter calibration, Master Meters are used as reference instruments. The following step-by-step procedure outlines how a calibration session is typically conducted using a Master Meter:

-

Air removal: Before starting calibration, circulate the product at the desired flow rate long enough to remove all air from the line and stabilize both pressure and temperature within the test circuit.

-

Reset counters: Reset both the master meter and the meter under test. Be sure to also reset the Vernier scale if a mechanical counter is used.

-

Set test volume: Calculate the test volume by multiplying the flow rate by two minutes, establishing a standard delivery quantity for accurate comparison.

-

Deliver product: Start and complete the delivery at a consistent, controlled flow rate.

-

Record volumes: After delivery, record the volume readings from both the meter under test and the master meter.

-

Temperature compensation: Adjust both volume readings to the standard temperature of 15 °C to ensure reliable comparison.

-

Calculate error: Determine the percentage error of the meter under test by comparing readings and applying the correction factors based on the master meter’s calibration curve.

-

Run tests at multiple flow rates: Perform at least two calibrations at maximum flow rate and one at minimum flow rate to verify accuracy across the entire operational range.

-

Use supporting instruments: The process is supported by additional equipment such as a flow rate indicator, unit drum, temperature and pressure gauges, and either electronic or mechanical counters with Vernier scales for fine reading resolution.

-

Ensure traceability: Each master meter is accompanied by a calibration certificate from an accredited laboratory, ensuring measurement traceability and compliance with international standards.

ISOIL flow meters calibration systems

What is a proving tank and how it works

Proving tanks work by comparing the volume of liquid measured by the meter and the known volume observed in the proving tank. During calibration, the liquid passes through the meter under actual or simulated operating conditions of temperature, pressure, flow rate, density, and viscosity. Then it is conveyed into the proving tank where its volume is determined thanks to the pre-set scale. In this way, the flow meter can be reset and aligned with national or international reference standards.

ISOIL can provide:

- Fixed proving tanks from 1 to 25.000 liters;

- Mobile proving tanks for easy fuel handling in oil terminals, ranging from 1.000 to 10.000 liters;

- Carbon steel or stainless steel structure;

- High-pressure version for LPG calibration.

Discover our proving tanks and master meters

How to use a Master Meter

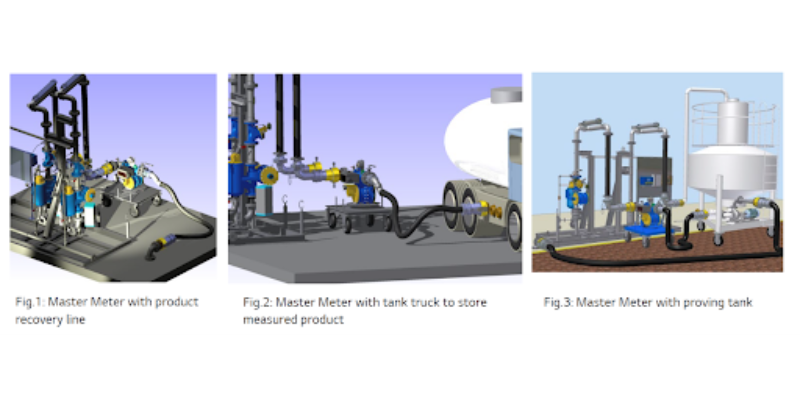

Master meters are high-precision meters dedicated to calibrating other meters in service at tank trucks loading bays or in transfer lines. They are more flexible and represent a good alternative to proving tanks since they only require one single operator and reduce operation time by approximately half.

These calibration systems can be mounted on trolleys with wheels so that they can be transported as close as possible to the meter to be adjusted. They can also be provided with further accessories upon request (temperature gauge, pressure gauge, ball valve kick plate for connection with anti-overfilling device, flexible hoses, etc.).

ISOIL test room for measurement

ISOIL plant is equipped with a test room which is accredited as a Calibration laboratory according to the ISO EN 17025, following its strict standards to provide calibration certificates recognized at European level. The accredited ISOIL laboratory called Metior (LAT certificate no. 108) performs volumes calibration s from 1 to 25.000 liters and calibration of PD meters with flow rates ranging from 5 to 12.500 L/min.

Since 1958, ISOIL stand alongside oil & gas and petrochemical companies offering solutions for fluid measurement granting the highest level of accuracy in complete compliance with national and international standards worldwide.

Are you in need of a flow calibration system?

Contact us

Contact us for more information about our services and products

Form sent successfully

Error