Side-stream blending

Fuel Blending

When we talk about fuel blending, we usually refer to the process that successfully manages to mix two or more products based on a specific percentage ratio. An example is that of the blend of diesel oil and FAME or petrol and ethanol, where we can clearly see the union of a hydrocarbon and a product of plant origin.

The fuel blending solutions by ISOIL are designed to provide strategic and operational advantages, including:

- cost savings on production time scales;

- excellent fuel blend versatility;

- high-quality standards of the blended product.

Would you like to know more about our fuel blending solutions?

Contact us

The Fuel Blending Process: How Does It Work?

The fuel blending process is a technique employed to combine different fuel stocks to produce a final product that meets specific requirements. To perform an optimal fuel blending process, it is fundamental to follow these steps.

Analysis Phase

First, you need to select different base stocks or raw fuels, such as naphtas, reformates, alkylates, and so forth. However, before blending, an assessment phase is performed to determine how these components will impact the output of the whole operation.

In fact, each component has intrinsic properties that can influence the final result, in terms of:

- octane number

- volatility

- density

- sulfur content

- emissions profile.

Highly skilled technicians formulate a fuel blend recipe using advanced technology and mathematical models. Through complex calculations, it is possible to understand the quality of the resulting blend, its specific properties and, if necessary, adjust the formulation.

Processing Phase

The process takes place in blending tanks. There are two main methods:

- batch blending, all the chosen components are mixed at once;

- inline blending, the components are continuously injected into a pipeline according to the formulation.

Quality Testing & Distribution

After fuel blending, the final product undergoes further testing to ensure that it meets all specified quality and regulatory standards. Additional adjustments may be required.

It is quite common to include additives in the blend to enhance certain features like stability, cold flow, corrosion inhibition.

Once the fuel blend resulting from the process has passed all the controls and tests, it is time to store it in tanks and distribute it to the market. Proper storage is the key to preserve the quality and integrity of the final product.

ISOIL Equipment Deals With Different Types of Fuel Blending

Over the years, we have earned a specific know-how that allows us to perform the blending process with different types of fuel. In fact, ISOIL can deal with:

- diesel fuel blending a specialized procedure that consists in merging various types of diesel oil to achieve a fuel mix with specific features. This method is executed by combining fossil-derived hydrocarbons with plant-derived products - such as biodiesel - to obtain a more environmentally friendly fuel.

- bioethanol blending with gasoline is another sustainable alternative to traditional fuel, as bioethanol is a renewable source with lower emissions. It is mainly produced from organic materials like corn and sugarcane and, when blended, it increases the oxygen content of the gasoline, facilitating cleaner combustion while greatly improving engine efficiency and performance.

- biodiesel blending with traditional diesel is an effective way to create a greener solution to conventional fuel sources, leveraging the organic and renewable nature of biodiesel. This fuel is produced with vegetable oils and animal fats, when blended, it enhances the environmental profile of diesel significantly reducing carbon footprint.

Would you like to know more about our fuel blending solutions?

Contact us

ISOIL Fuel Blending Equipment: The VEGA 3 Multi-Counter Stream Flow Computer

To deal with all these types of blending, ISOIL has developed the VEGA 3 multi-counter stream flow computer. This fuel blending device is the perfect piece of equipment for boasting the accuracy of each blending process.

In fact, this electronic counter can master multiple fuel blending architectures, including: sequential ratio, side stream and differential blending, becoming an indispensable tool for the Oil & Gas industry.

Furthermore, VEGA 3 is engineered to support up to six measuring systems and handle up to twelve meters, thus providing a versatile solution that can easily adapt to different operational scales and customization.

Are you interested in our fuel blending equipment?

Contact us

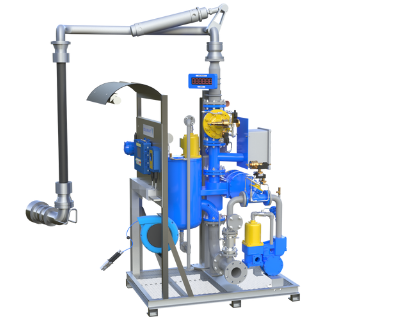

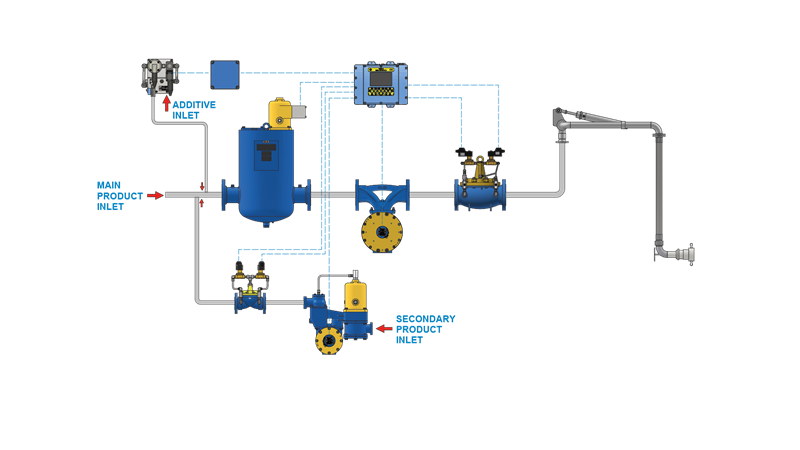

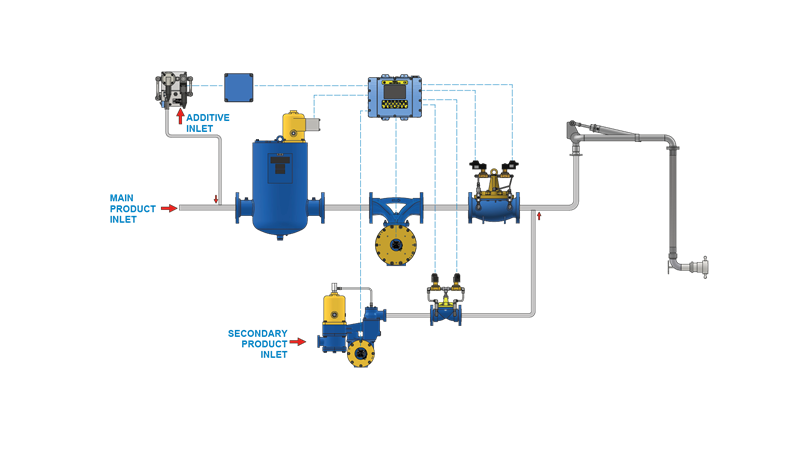

ISOIL is able to supply various types of blending skids. According to the customer’s needs, the system can be designed to be installed on the transfer line to the tank or directly at the loading point.

The control core of blending operations is the VEGA 3 electronic counter, capable of managing various blending architectures, depending on the application needs and fiscal and regulatory framework:

- Sequential blending

- Ratio blending

- Side stream blending

- Differential blending

Ratio blending

Markets

ISOIL depot solutions are the apex of our 60-year plus experience in the sector. From tank truck loading and unloading, from additive injection to adulteration for subsidised products, ISOIL is able to provide solutions ranging from the individual meter to complete and engineered skid solutions where all the components are already assembled and wired, resulting in a system ready for installation.

ISOIL stands out for its ability to customise products based on the Customers’ specific requests, even when they differ from standard.

We follow the entire process at 360 °, even after installation we ensure all the assistance necessary to ensure efficiency and safety for our customers.

Contact us for more informations about our services and products

Form sent successfully

Error